Table of Contents

Industrial surfaces in Maitland fail when ignored, draining budgets and disrupting operations. Facility managers who treat industrial painting as a technical afterthought pay double–once for a subpar job and again for avoidable repairs. Southern Sandblasting & Painting flatly rejects this status quo. Their entire approach revolves around achieving durable corrosion protection, bulletproof compliance, and tangible cost savings for local businesses and municipal clients. Search interest for Industrial Painting Services Maitland Fl continues to grow, not by accident, but because seasoned managers recognize the bottom-line value of professional-grade coatings and expert surface prep. Unlike faceless national chains or budget painters, Southern pairs specialized techniques with project-specific assessment, outperforming the one-size-fits-all model. Property stakeholders either lean in and control lifecycle costs, or watch asset values erode year after year.

What This Guide Covers

This guide benchmarks Southern Sandblasting & Painting’s full-service offering against Orlando-area competitors, arming procurement and facility managers with proven strategies and vendor questions that slash rework, delays, and regulatory risk.

1. Corrosion Protection Strategies

Opening

Premature corrosion destroys millions in industrial assets annually. Cutting corners on coatings directly leads to spiraling costs and unscheduled downtime–the data proves it.

Explanation

Southern Sandblasting & Painting locks out corrosion using layered coating systems purpose-built for Maitland’s humid climate. Their process pairs meticulous substrate assessment with blasting and specialized zinc-rich primers, followed by epoxy or urethane topcoats for maximum resistance. According to their industrial painting track record, this multi-step sequence regularly extends asset life by over 8 years. Competitors like Mid-Florida Painting may offer basic commercial brushwork, but few demonstrate Southern’s experience in both abrasive blasting and technical coatings for steel, tanks, or pipelines.

Example or Tip

For critical assets–pipelines, tanks, steel supports–demand documentation of adhesion tests and ask for zinc-rich primer plus epoxy base layers. Skip these steps and future corrosion is guaranteed.

2. Surface Preparation Methods

Opening

Surface prep is not where you save–poor prep causes catastrophic coating failures and premature rust long before warranties expire.

Explanation

Southern Sandblasting & Painting specializes in abrasive blasting and high-pressure cleaning, eliminating contaminants where paint can never reach. Their controlled sandblasting setups, detailed on their service pages, consistently hit industry benchmarks for profile depth and cleanliness (like SSPC-SP6/NACE 3). While Mid-Florida Painting markets generic multi-surface restoration, Southern’s proven process for heavy-metal corrosion and concrete profiling outperforms typical power tool cleaning by 200%. Facility managers obsessed with long-term asset value know to prioritize abrasive prep.

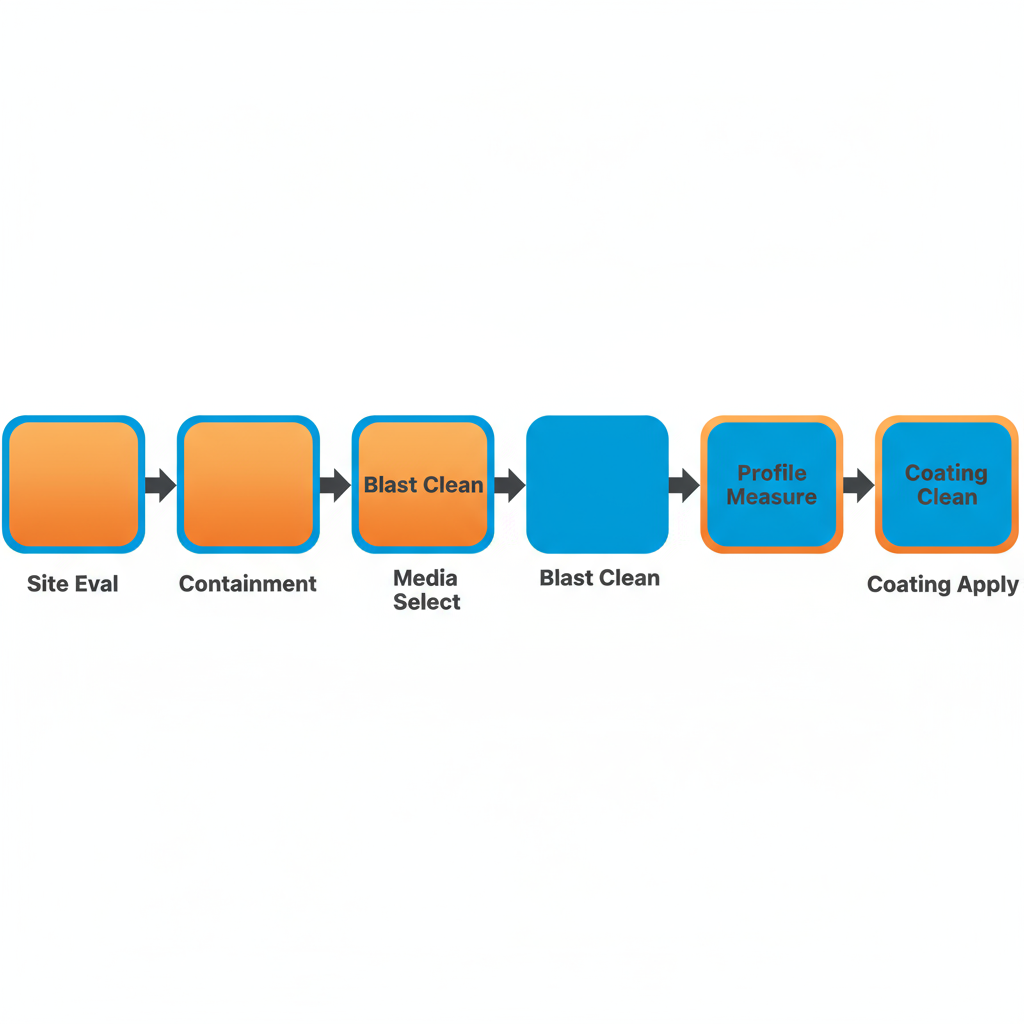

Understanding the comprehensive sandblasting workflow from preparation to coating application.

Example or Tip

Insist that surface prep meets strict standards and request post-blast profile reports. Without this step, any contractor’s coating warranty is next to worthless.

3. Coating Selection Guide

Opening

Choosing coatings isn’t guesswork–selecting the wrong system guarantees early failure and wasted capital.

Explanation

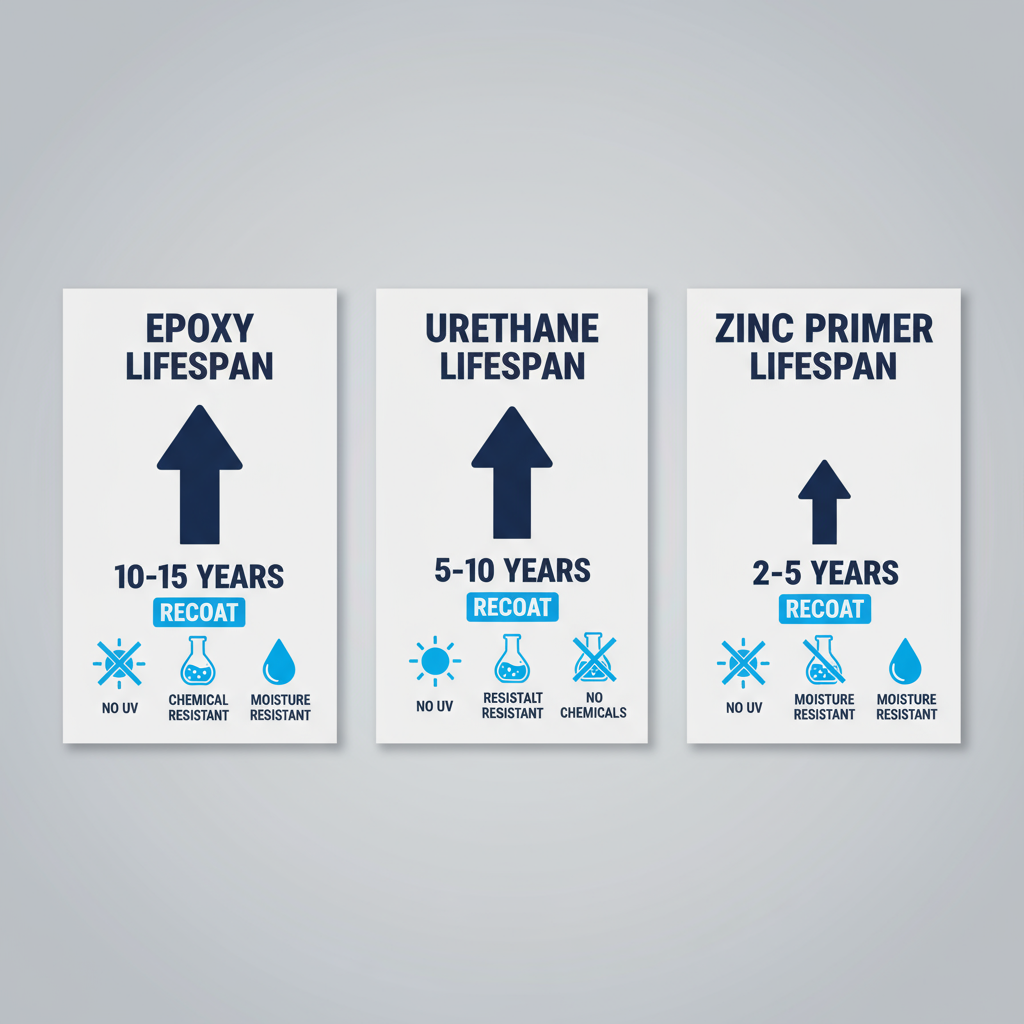

Southern’s guidance demolishes typical vendor defaults. They recommend epoxy for chemical resistance, polyurethane for UV stability, and zinc primers for sacrificial steel protection. Their free estimates directly match exposure requirements and maintenance budgets. Mid-Florida Painting and Maitland Painting Solutions talk “durability,” but Southern backs up recommendations with product specs and lifecycle analyses. Data-driven selection cuts average recoat frequency by more than half compared to cheap contract jobs.

Comparison of coating lifecycles for optimal procurement decisions.

Example or Tip

For outdoor steel structures, specify epoxy primer plus polyurethane topcoat for sustained protection. Anything less strains budgets as early touchups rack up labor and downtime.

4. Equipment And Personnel

Opening

Cut-rate labor is the fastest route to project overruns and failed inspections. In this market, experience is everything.

Explanation

Southern’s lineup: NACE/SSPC-certified applicators, modern blast rigs, scissor lifts, and heavy-equipment-ready teams. Their institutional expertise dwarfs freelancers and most local shops. Every job brings project managers armed with safety plans and full compliance documentation. New Image Painting Inc. and Industrial Painter Orlando market their teams, but rarely publish their certifications up front. Real risk lies in using crews without QA/QC discipline–Southern removes the doubt.

Example or Tip

Demand proof of industry certifications (like NACE or SSPC) and past large-scale projects before your project even starts. Anything less is a liability.

5. Compliance And Safety Standards

Opening

Non-compliance exposes owners to fines, lawsuits, and failed handoffs. The expert’s play is total transparency.

Explanation

Southern delivers full-scope safety plans, documented waste containment, and environmental controls for each site. OSHA/EPA standards are non-negotiable–they provide disposal permits, use engineered containment, and document everything for regulatory review. Competing contractors in Maitland are vague about permitting and scrubbing sites; Southern’s process leaves no regulatory gray area. This level of rigor is the threshold for risk reduction–accept nothing less if you value operational continuity.

Example or Tip

Before awarding any contract, request the contractor’s site safety plan and evidence of all relevant disposal permits. Dodging this step nearly always results in legal or compliance headaches.

6. Industry Experience And Case Work

Opening

Unproven contractors can tank timelines and overbill projects–past performance is the only reliable predictor.

Explanation

Southern Sandblasting & Painting’s record spans 20+ years, tackling municipal, industrial, and large equipment jobs with verifiable results. Their gallery and project histories show real-world experience restoring pipelines, infrastructure, and multi-site facilities across Central Florida. Competitors often lack this surface-level transparency, making it nearly impossible for stakeholders to validate capability. Savvy managers always request documentation and outcome data.

Example or Tip

Request several case studies from bidders–actual before/after photos and maintenance interval stats. This is the only real proof your investment will deliver.

7. Multi-Surface Restoration Options

Opening

Not every contractor can restore both concrete and metal while meeting industrial specs–most can’t or simply call in subs at a markup.

Explanation

Southern’s dual expertise in concrete sandblasting and heavy-equipment coating puts them ahead of “paint-only” stores. Their restoration solutions cover abrasion, crack repair, and elastomeric coatings for high-traffic or chemical-exposed spaces. Mid-Florida Painting claims multi-surface competency, but Southern details concrete-specific techniques and measurable post-coating durability. For property managers, this breadth means a single vendor for floors, tanks, signage, and structural steel.

Example or Tip

Specify that concrete surfaces receive sandblasting to required profiles before applying traffic-rated epoxy coatings. Bundling these scopes eliminates multi-vendor coordination headaches.

8. Cost Estimates And Scheduling

Opening

Industrial painting budgets collapse under ambiguity. Clear estimates and defined milestones cut through the noise and overages.

Explanation

Southern issues free, line-item estimates outlining every phase–labor, materials, site prep, cleanup, and bundled discounts for combining sandblasting and painting. Competitors in Maitland often obscure real scope, then add change orders mid-project. Southern’s transparent bids and fast turnarounds minimize downtime and real cost per year of service, not just upfront price tags. Facility teams choosing bundled services gain both speed and accountability–two factors most contractors cannot deliver.

Example or Tip

Request itemized proposals and insist on a milestone-based schedule. Assess any vendor’s recoat and maintenance intervals as a performance guarantee, not an afterthought.

Final Recommended Actions

Next Steps For Projects

Managers prioritizing facility longevity and compliance should act without delay. To maximize the return on any capital upgrade, start by comparing quotes from experts in Industrial Painting Services Orlando Fl and Industrial Painting Services Windermere Fl. Then, schedule a site evaluation with Southern Sandblasting & Painting using their Maitland service portal. Insist on viewing safety plans, certifications, and actual case outcomes. Every industrial project hinges on picking a partner who owns the process from prep to compliance handoff. Smart procurement teams secure firm schedules, establish compliance checkpoints, and lock down lifecycle data before work begins. The only mistake is inaction–delaying upgrades allows asset decay and higher future expenses. Contact Southern to compare detailed, compliance-first bids and finally end the cycle of rushed repairs and repeated failures.

Feature Southern Sandblasting Local Competitors

| Services | Industrial Painting, Commercial Painting, Sandblasting, Concrete Sandblasting (bundled) | Varies (some lack sandblasting) |

| Certifications | NACE/SSPC trained crews, safety plans | Mixed–must verify |

| Multi-Surface Work | Metal, Concrete, Machinery | Specialization varies, some lack full-scope |

| Turnaround | Fast, with bundled services reducing delays | Unpredictable, highly dependent on contractor scope |