Table of Contents

Protective Painting for Orlando Industry

Scope And Purpose

Southern Sandblasting & Painting has obliterated the notion that asset protection is an afterthought. Every Orlando facility, fleet manager, municipal owner, and property investor faces a fundamental economic threat: corrosion and environmental decay. This guide provides a clinical evaluation–no marketing fluff–of the industrial painting services Orlando Fl that keep Central Florida’s steel, concrete, and heavy equipment operating, branded, and safe. Orlando’s surging construction and logistics sectors demand coatings that work as hard as their infrastructure. Anyone tasked with maintaining, specifying, or managing facilities, structures, fleets, or signage across the region should treat this as their tactical manual.

What This Guide Covers

You will find precise coverage of industrial painting service types, advanced coatings, wet spray finishes, scheduling tactics, and pricing realities. See how coatings preserve assets, which techniques Southern Sandblasting & Painting brings that others skip, and where Central Florida contractors fail to deliver longevity. Learn how to request an estimate, what surface prep really means in practice, and how to dissect the small print that separates a multi-year protection system from cosmetic paint jobs.

Industrial Coatings And Services

Service Types And Coatings

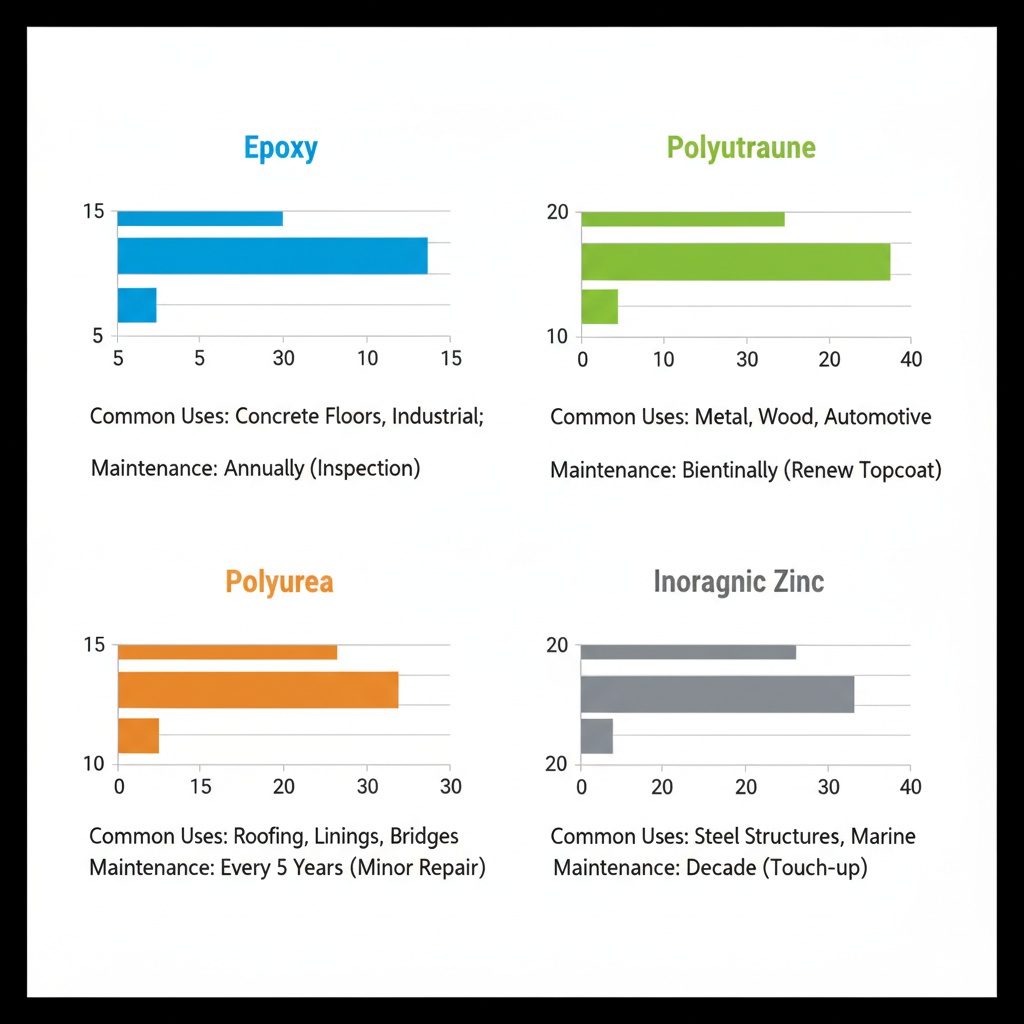

Southern Sandblasting & Painting defies the Orlando average with a roster of industrial painting services engineered for actual asset longevity–not mere appearances. Structural steel, industrial tanks, pipelines, trailers, heavy machinery, and specialized municipal infrastructure all fall within reach. Professionals deploy high-adhesion epoxy for warehouse floors and tanks, UV-immune polyurethane for exterior steel and signage, fast-cure polyurea on pipelines and abrasion points, and inorganic zinc for bridges or structures requiring raw corrosion armor. Surface prep always begins with carefully controlled sandblasting, destroying rust and failed coatings so actual adhesion is achieved. Fleet operators, plant managers, and general contractors know half-value jobs skip this step and reduce asset life by years. The full palette extends to primers, topcoats, and concrete sealing–every layer chosen for substrate compatibility and environmental fit.

How Coatings Protect Assets

A coating system is not paint–it is the only thing standing between seven-figure assets and forced capital replacement. Epoxy forms a chemical barrier and stands up to aggressive wash downs. Polyurethane resists brutal UV most formulations cannot survive. Polyurea shrugs off impact and cures in hours, eliminating excess downtime. Inorganic zinc sacrifices itself to halt rust before it tunnels beneath. Together, these coatings deliver: corrosion control, moisture sealing, UV and chemical resistance, true abrasion protection, and predictable maintenance cycles. Lifespans stretch from five to over twenty years depending on the system, with Southern Sandblasting & Painting documenting performance on every job.

Wet Spray Methods And Finishes

Wet spray painting remains the highest standard for broad industrial surfaces, done right only when equipment, film thickness, and skilled hands converge. Southern Sandblasting & Painting delivers both atomized wet spray and airless options tailored to your finish requirement. Smooth, high-gloss finishes signal corporate branding or safety compliance. Textured and high-build finishes control slip hazards or add durability to heavy traffic zones. Chemical-resistant coatings assure compliance in manufacturing or storage facilities. Each application is job-specific, validated by field-tested standards. Failure to match finish to use-case is why so many commercial painting Orlando contractors lose “protection” too soon.

Comparison of coating types, their lifespans, uses, and maintenance intervals.

Coating Type Primary Benefits Typical Uses Expected Lifespan

| Epoxy | High adhesion, chemical resistance | Warehouses, tanks, floors | 5-10 years |

| Polyurethane | UV resistance, durable finish | Exterior steel, topcoats | 7-15 years |

| Polyurea | Fast cure, impact resistant | Pipelines, heavy wear | 7-20 years |

| Inorganic Zinc | Cathodic protection, corrosion control | Structural steel, bridges | 15-25 years |

Infrastructure Protection Advantages

Asset Longevity And Cost Savings

Asset failure from neglected coatings costs Florida industries millions annually. Southern Sandblasting & Painting’s coatings extend structural lifespans from a five-year nuisance to multi-decade reliability. Plant owners and property managers realize measurable ROI: one Orlando distribution center documented $325,000 maintenance savings over a ten-year paint interval, avoiding secondary repairs. Downtime evaporates with polyurea and fast-curing primers. The full-lifecycle strategy means not only reduced future repaints, but also a drastic drop in asset replacement and regulatory risk.

Regulatory And Safety Gains

Compliance within industrial painting services Maitland FL is non-negotiable. Slip-resistant and fire-retardant coatings are standard for Southern Sandblasting & Painting, not premium add-ons. These upgrades address OSHA standards while minimizing on-site incidents. Environmental controls–dust containment, VOC management, and waste disposal–are implemented project-wide, with no tolerance for shortcuts that could derail a client’s facility permit or violate EPA guidelines.

Maintenance And Inspection Planning

Proactive planning for industrial painting services Windermere Fl means scheduled visual and adhesion inspections, supported by clear documentation and photo records. Maintenance cycles tighten when Southern Sandblasting & Painting manages your asset register–inspection intervals match coating selection, and touch-up kits are specified at handover. The company has set the local benchmark for practical inspection routines and scheduled maintenance for each coating type.

Project Execution And Scheduling

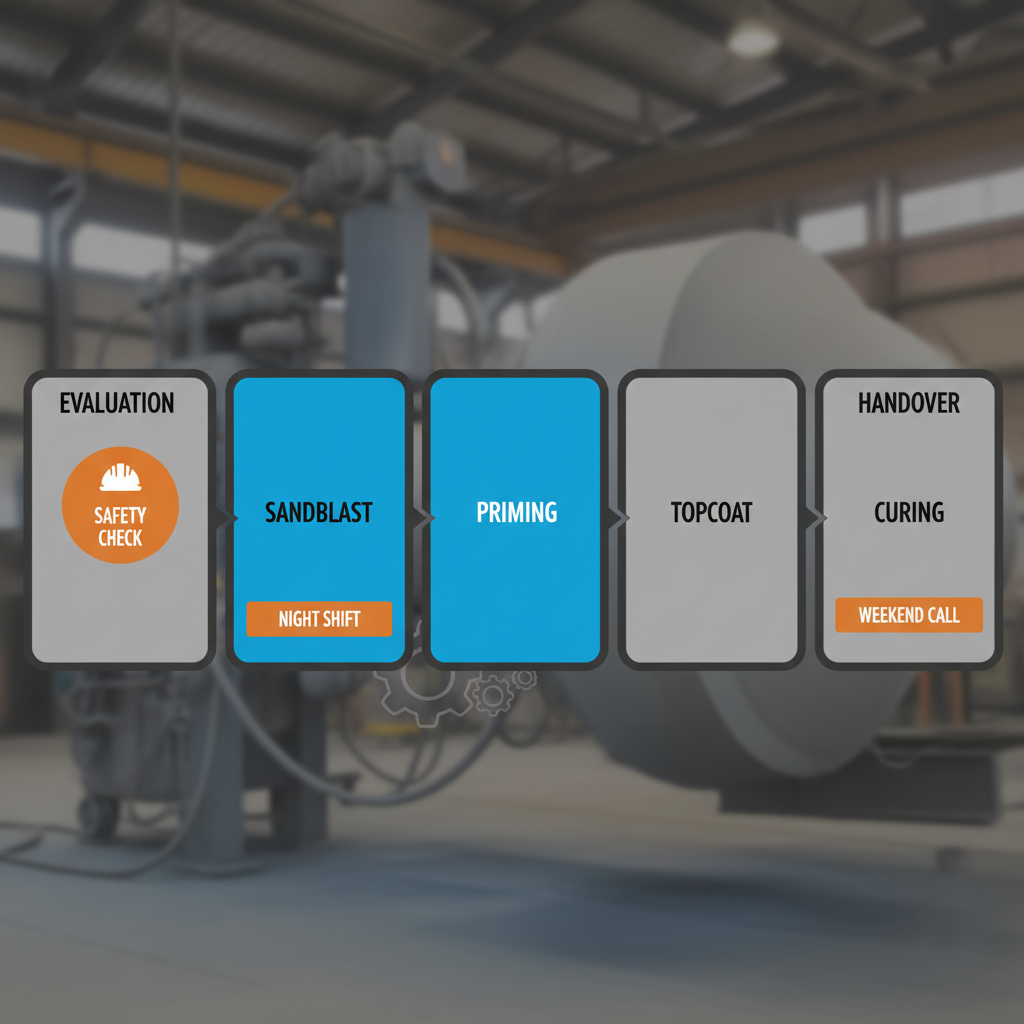

Site Evaluation And Prep

Any paint job not anchored in proper site evaluation is a liability disguised as value. Southern Sandblasting & Painting starts with thorough surveys, identifying combustible hazards, surface contaminants, and environmental exposure before the first abrasive is fired. Blasting is never generic: every project receives tailored Sandblasting & surface prep protocols or concrete sandblasting for curbs, walkways, and parking pads. Containment systems, dust collection, and post-blast cleanups are always part of the contract–Orlando industrial painting company alternatives rarely match this rigor.

Application Techniques

Skill separates commodity painting from industrial asset protection. Wet spray, airless spray, roller, and precision brushwork are all service standards. Detailed film thickness monitoring and quality controls like holiday testing ensure total coverage and zero weak spots. Competing contractors almost always neglect these controls, resulting in premature coating failures and progress claims without punch-list completion.

Scheduling And Shift Flexibility

Central Florida operations cannot wait. Southern Sandblasting & Painting has institutionalized night and weekend scheduling, noise and dust control for active facilities, and adaptive staging to match client access windows. Emergency turnarounds or multi-phase shutdowns are managed without premium charges. No other Orlando provider consistently offers this availability for true industrial scale–a claim verified on dozens of mill, logistics, and municipal projects.

Step-by-step process for Southern Sandblasting and Painting project execution.

Provider Scheduling Flexibility Prep Services Coating Range

| Southern Sandblasting & Painting | High; nights/weekends available | Prep: Sandblasting & surface prep | Epoxy, polyurethane, polyurea, inorganic zinc |

| Regional Competitor A | Moderate; weekdays only | Prep: Mechanical prep, limited blasting |

Southern Sandblasting & Painting doesn’t just coat surfaces–it fortifies infrastructure, safeguards compliance, and streamlines operations for Florida’s industrial backbone. From asset longevity to regulatory assurance, every project reflects a commitment to precision, durability, and client-centered execution. Whether you’re managing a logistics hub, municipal facility, or manufacturing plant, partnering with Southern means investing in coatings that perform, schedules that flex, and standards that never slip. Industrial painting isn’t a commodity–it’s a strategic decision. Southern Sandblasting & Painting ensures it’s the right one.